Stainless Steel Investment Casting is

an industrial process based on lost-wax casting, one of the oldest known

metal-forming techniques. The term "lost-wax casting" can also refer

to modern investment casting processes.

Water glass and silica sol investment

casting are the two primary stainless steel investment casting methods

nowadays. The main differences are the surface roughness and cost of casting.

Water glass method dewaxes into the high-temperature water, and the ceramic

mold is made of water glass quartz sand. Silica sol method dewaxes into the

flash fire, and silica sol zircon sand makes the ceramic mold. Silica sol

method costs more but has the better surface than the water glass method.

The process of stainless steel investment

casting can be used for both small castings of a few ounces and large castings

weighing several hundred pounds. It can be more expensive than die casting or

sand casting, but per-unit costs decrease with large volumes. Investment

casting can produce complicated shapes that would be difficult or impossible

with other casting methods. It can also produce products with exceptional

surface qualities and low tolerances with minimal surface finishing or

machining required.

Auwell stainless investment casting,

the normal material is 304, 304L, 316, 316L and DSS (Duplex Stainless Steel). Recently,

we developed 1.4581 stainless steel investment casting parts for a German

client for paper industry. Auwell stainless steel investment casting, the size

limits are 3 g (0.1 oz) to several hundred kilograms. The cross-sectional

limits are 0.6 mm (0.024 in) to 75 mm (3.0 in).

The process of the stainless steel

investment casting:

-마스터 패턴 생성

-금형 만들기

-왁스 패턴 생성

-왁스 패턴 조립

- Apply investment materials

-탈 왁스

-번 아웃 예열

-붓는 것

- Divesting

- Finishing

스테인리스 강 투자 주조의 장점 :

- Excellent surface finish

- High dimensional accuracy

-매우 복잡한 부품은 주조 가능

- No flash or parting lines

Auwell Advantages

- Rich Experience

특히 유럽 및 북미 시장에서 스테인리스 스틸 인베스트먼트 주조 제품 개발 및 생산 분야에서 20 년 이상의 경험을 쌓았으며 전 세계의 재료, 기술 및 품질 표준에 대한 확실한 이해를 가지고 있습니다.

-빠른 처리

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 2 weeks

for simple projects.

-포괄적 인 솔루션 제공 업체

Auwell provides

comprehensive services for stainless steel investment casting projects starting

from designing, through prototyping, tooling/fixture development, sampling,

mass production, and to logistic and post-sale support.

- Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. For quality control of casting parts, we provide set

of test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-유연한 지불 기간

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

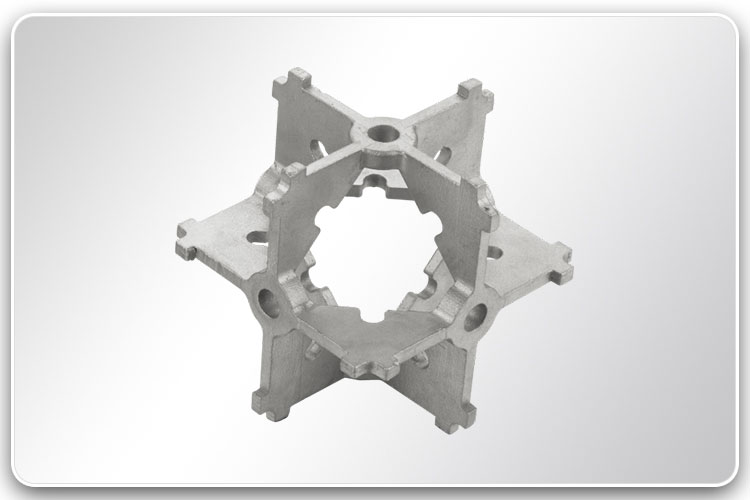

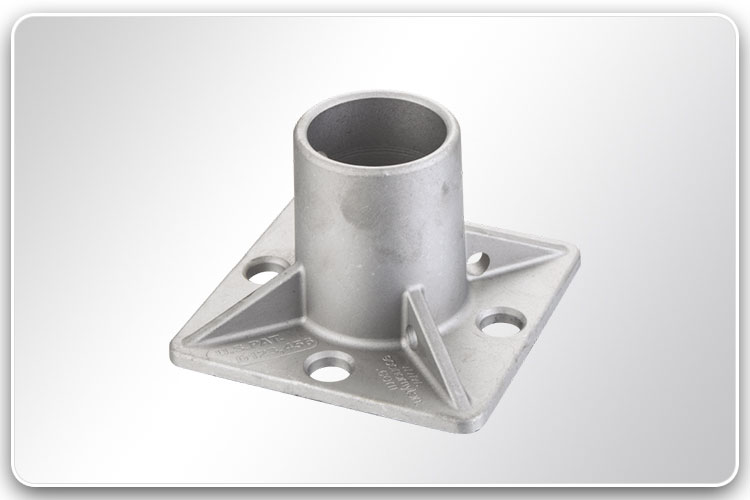

다음의 스테인리스 강 인베스트먼트 주조 부품 카탈로그는 Auwell이 세계적으로 저명한 고객에게 생산 및 공급 한 카탈로그입니다. 자세한 내용은 관련 사진을 클릭하십시오. 대부분의 제품은 데모 용으로 만 사용됩니다.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик