기술

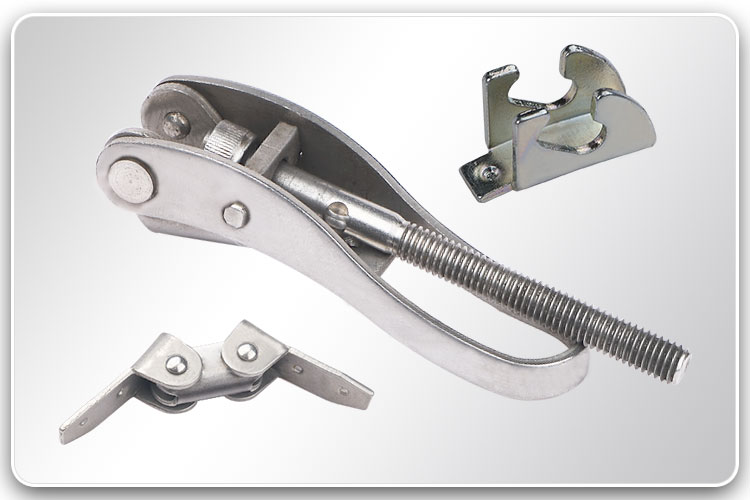

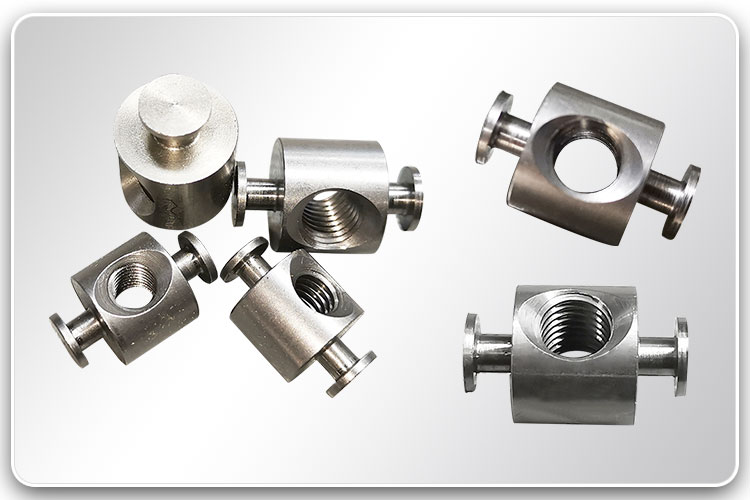

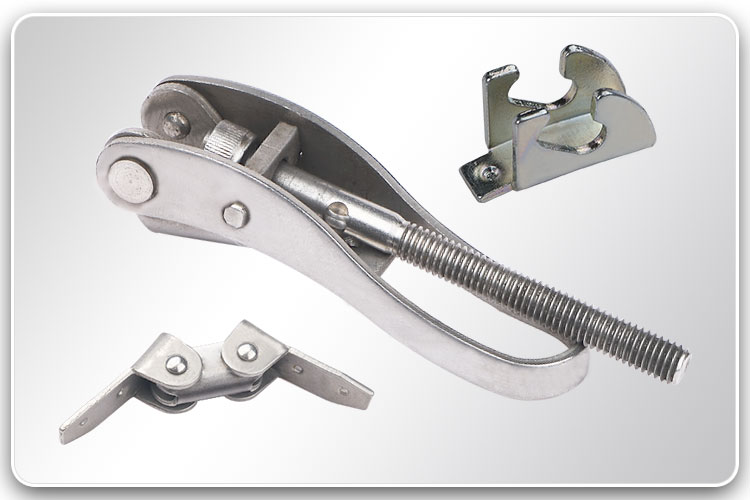

Turning parts for clamping rings are the essential components for clamping ring products. If the closing side of the ring is jointed with saddle and bolt, one clamping ring set consists of generally 4 turning parts. Φ12mm and Φ14mm are the most popular diameters. A set of clamping ring consists 2 of turning parts for the clamping rings, for Φ12mm diameter, one with 6.5mm section hole and M6 thread hole for another, likewise, Φ8.5mm holes and M8 thread holes for Φ14mm turning parts for the clamping rings.

클램핑 링용 탄소강 선삭 부품에는 아연 도금 표면이 있으며 기본값은 흰색 아연 도금입니다. 쉽게 식별 할 수 있도록 나사 구멍이있는 회전 부품은 노란색 아연 도금으로 코팅되어 있습니다.

클램핑 링 제어를위한 선삭 부품의 중요한 포인트에는 암 영역의 직경 공차, 트레드 구멍의 품질 및 나사 구멍 태핑 영역 주변의 버가 포함됩니다. 단순 해 보이지만 올바른 프로세스와 기계가 없으면 품질 문제가 쉽게 발생할 수 있습니다.

With 15 years of professional turning parts for the clamping rings production experience, Auwell has developed the most efficient way of producing such turning parts.

다음 비디오는 클램핑 링을위한 선삭 부품의 제조 공정을 보여줍니다.

Currently, 100% of our turning parts for clamping rings are exported to Germany for our distinguished clients. By using optimized technology and programming, our products are proven to have excellent quality while having an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

The Turning Parts for Clamping Rings displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

기술 사양

-Material: ST12, ST37, Q235B, Stainless steel 304, 316L or upon request

-Turning parts: Diameter: Φ12mm with M6 thread orΦ14mm with M6 thread or upon request

-Surface treatment: zinc plating, or blanc for stainless steel

-Package: plastic bag, carton then wooden box.

장점

-풍부한 경험

More than 15 years of experience in this particular turning parts for clamping rings development and production, especially to the European markets. With solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

일반적으로 영업일 기준 2 일 이내에 견적을 제공합니다. 최신 제조 기술과 시설을 결합한 Auwell은 단 1 주일 만에 링 샘플 클램핑 용 선삭 부품을 제공 할 수 있습니다.

-포괄적 인 솔루션 제공 업체

Auwell은 설계부터 프로토 타이핑, 샘플링, 대량 생산, 물류 및 판매 후 지원에 이르기까지 클램핑 링 프로젝트의 선삭 부품에 대한 포괄적 인 서비스를 제공합니다.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-유연한 지불 기간

For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

관련 상품

Saddle for Clamping Rings

Saddle for Clamping Rings

클램핑 링용 고속 커넥터

클램핑 링용 고속 커넥터

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик