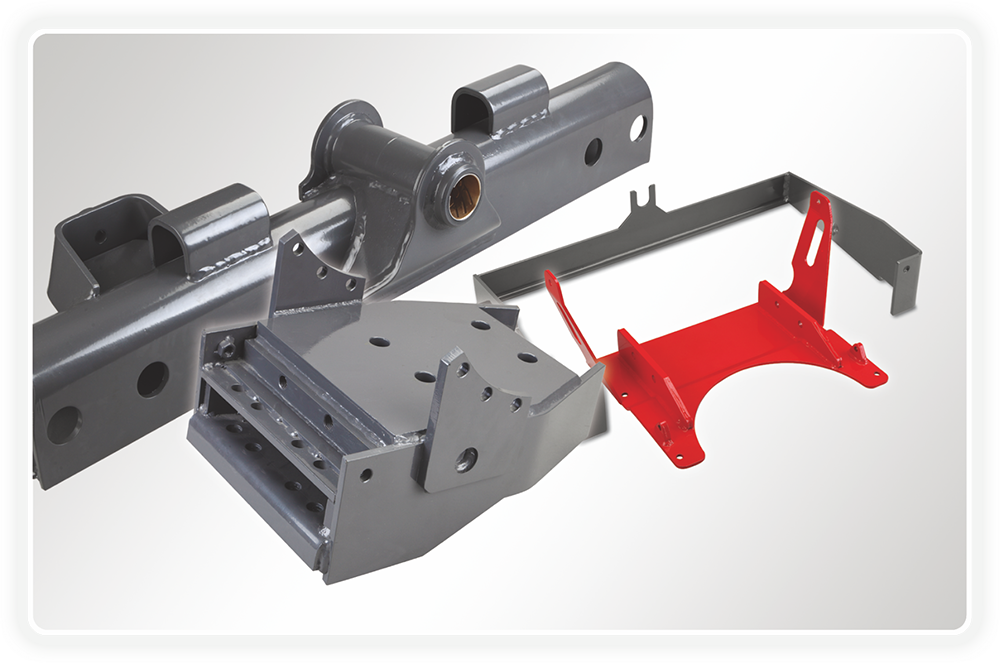

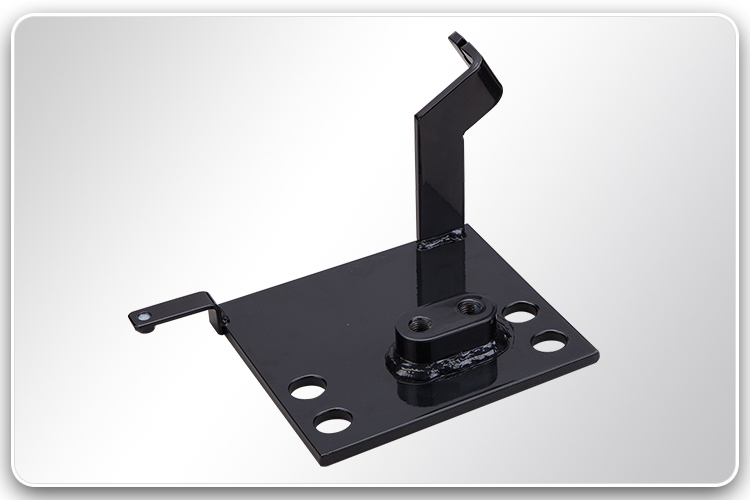

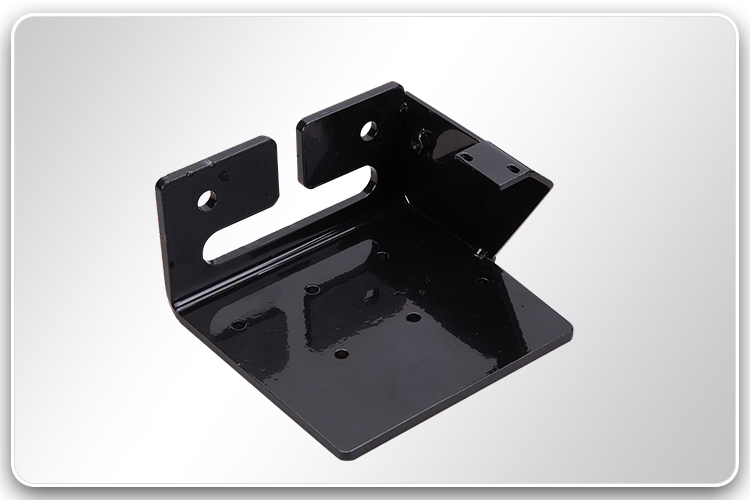

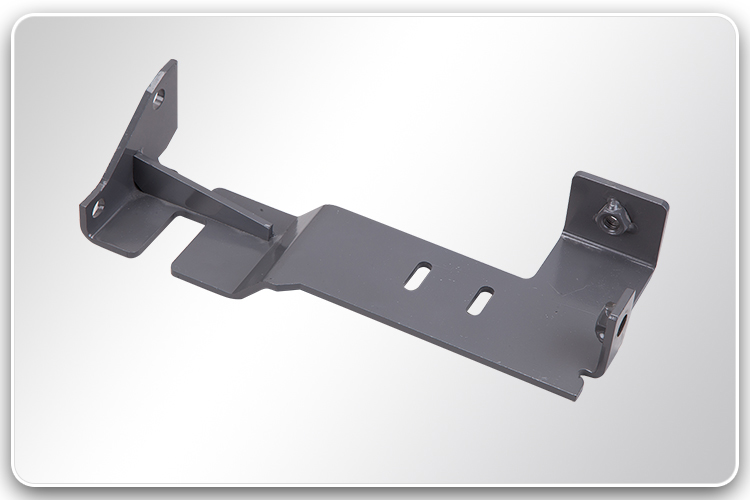

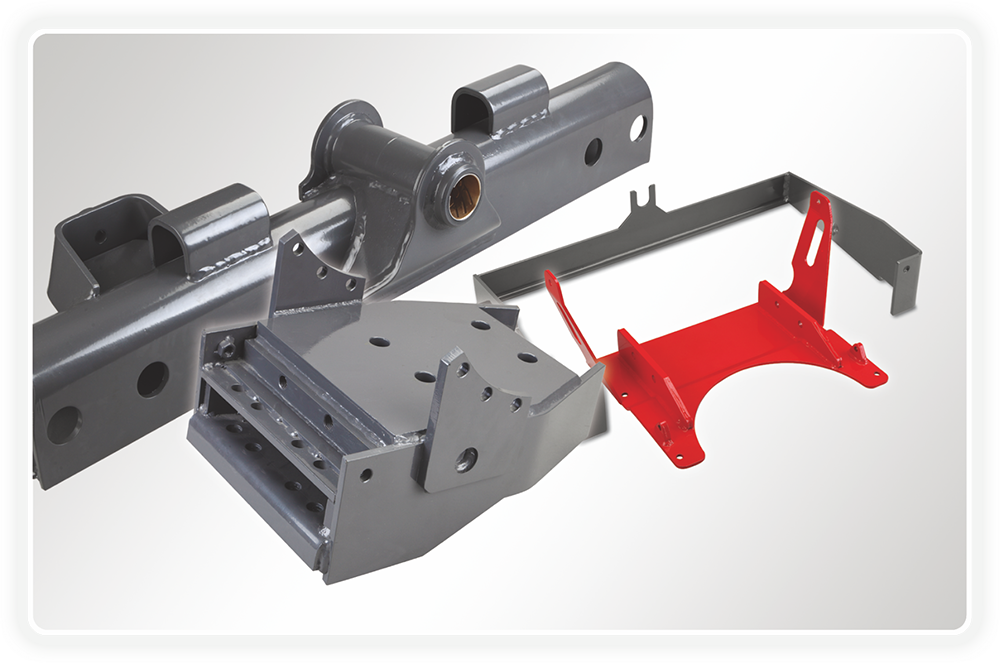

Auwell은 주로 AGCO MASSEY-FERGUSON BX200 시리즈를 위해 2011 년 판금 농업 기계 OEM 부품 개발을 시작했습니다. 간단한 스탬핑 부품부터 중장비 및 복잡한 조립 그룹에 이르기까지 다양한 분야를 다룹니다.

Agriculture Machinery industry has its own unique requirements, it is critical to use right material and manufacturing process in accordance with the drawing requirements. Auwell organizes the production of Agriculture Machinery OEM Parts from TS16949 registered and experienced manufacture to ensure the product quality.

The process of Agriculture Machinery OEM Parts manufacturing includes 4 steps - cutting, forming, assembling, and surface treatment.

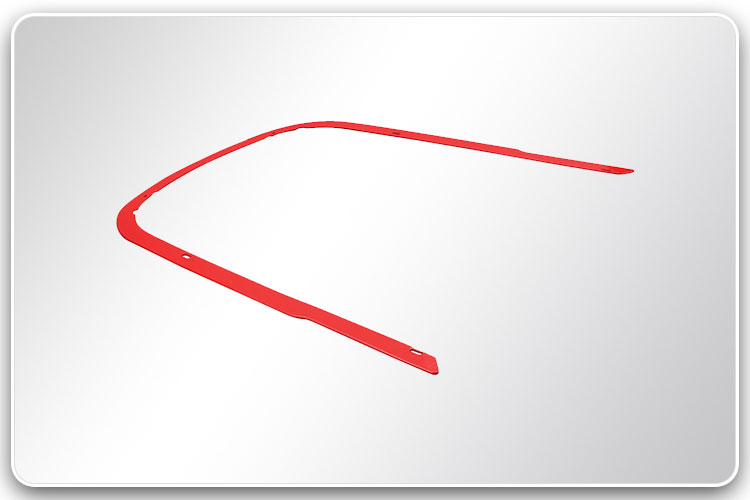

-절단 공정

We offer various cutting options with thickness ranged from 1 mm to 150mm, this includes oxygen cutting, laser cutting, plasma cutting. For small parts, the stamping is the most common way for material blanking.

-성형 공정

The forming process typically includes bending, hydraulic press forming with die, punching, and milling. The nature of the parts’ design determines the method used. Deburring is an essential procedure before welding and assembling.

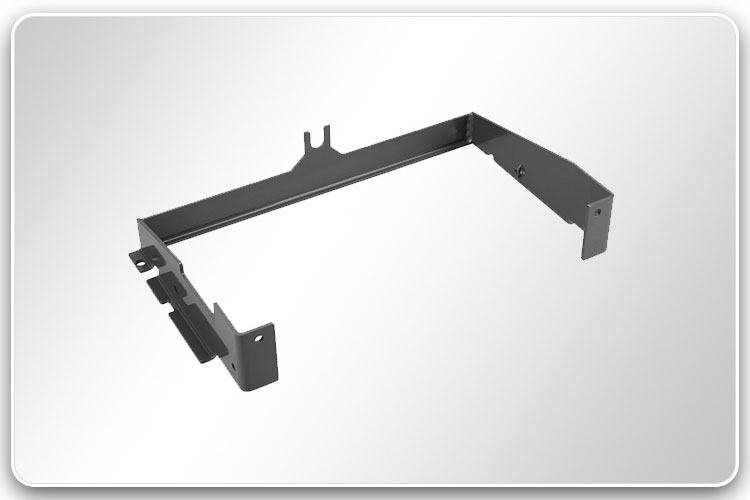

-조립

농업 기계 OEM 부품의 경우 조립의 주요 프로세스는 용접입니다. 용접 후 왜곡이없는 제품을 보장하기 위해 고정물을 미리 설계하고 제작해야합니다. 일부 영역은 조립 후 밀링이 필요합니다. 품질 검사를 위해 테스트 게이지 세트가 사전 개발되어 제품의 완전한 기능을 보장합니다.

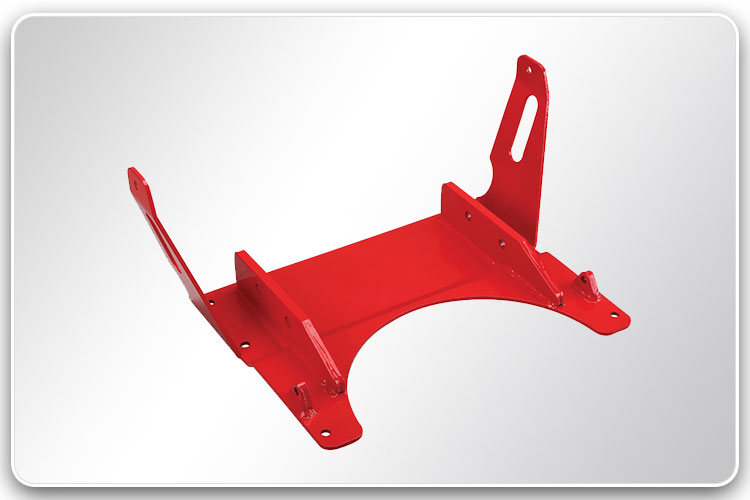

-Surface Treatment

The normal surface treatment processes of Agriculture Machinery OEM Parts include electrophoresis (KTL), powder coating, painting, and zinc plating. For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request. Anodizing is available for aluminum materials.

Technical Specifications

-Material

Mild steel, stainless steel, copper, brass, aluminum, and alloy steel.

-Machine capacity

1,200 ton hydraulic press machine, 800 ton stamping machine, material cutting thickness up to 150mm for oxygen cutting, 60mm for plasma cutting, and 25mm for laser cutting. Maximum part size: 2,000*1,500mm.

-기타 사양

Auwell is capable in designing and developing necessary tools for Agriculture Machinery OEM Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Surface treatment includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production. PPAP documents are submitted together with the initial samples.

Advantages

-Rich Experience

농업 기계 OEM 부품 개발 및 생산, 특히 유럽 및 북미 시장에서 9 년 이상의 경험을 바탕으로 전 세계의 재료, 기술 및 품질 표준에 대한 확실한 이해를 가지고 있습니다.

-빠른 처리

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 3 weeks for simple projects.

-Comprehensive Solution Provider

Auwell provides comprehensive services for Agriculture Machinery OEM Parts starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-엄격한 QC 정책

가장 엄격한 품질 정책은 자재 관리에서 시작하여 농업 기계 OEM 부품 주문에 대한 최종 선적 전 검사까지 이어집니다. 재료 인증서에는 공장 인증서, 타사 화학 성분 및 기계적 특성 보고서는 물론 요청시 RoHS 및 REACH 보고서가 포함됩니다. 다른 보고서에는 치수 검사, 표면 처리 두께 및 염수 안개 테스트 보고서 등이 포함됩니다. 우리는 생산 전에 공정을 구성하고 흐름도 및 제어 계획을 생성하여 모든 QC 공정이 TS16949 요구 사항 및 도면 사양을 준수하는지 확인합니다.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

The following catalogues of Agriculture Machinery OEM Parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик