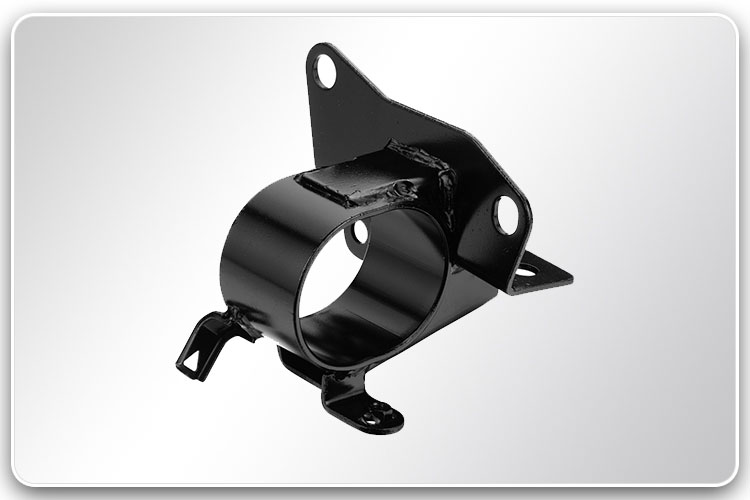

Custom made parts, pictures displayed are for demonstrating our product range and manufacturing capabilities뿐. 클라이언트가 유사한 제품을 개발해야한다면contact us for details.

Auwell has rich experience in end cup bracket products development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

Generally, we provide a quotation for end cup bracket in 3 working days. Combining the latest manufacturing technologies and facilities, Auwell is able to provide fast 3D printing end cup bracket prototypes in just a week for simple projects.

Auwell provides comprehensive services for end cup bracket products development starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

모든 엔드 컵 브래킷 제품에 대해 Auwell은 최적화 된 제조 공정을 활용하여 합리적이고 경쟁력있는 가격으로 제품 품질을 보장합니다. Auwell은 요청에 따라 맞춤형 브랜딩, 색 구성표 및 패키지 솔루션을 제공합니다.

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection for our end cup bracket products manufacture. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional inspection, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

대량 생산을 위해 엔드 컵 브래킷 주문에 대해 유연한 지불 조건을 제공하고 합리적인 신용 조건이 제공되며 고객은받은 엔드 컵 브래킷에 만족할 때만 지불합니다. 장기 프로젝트의 경우 빠른 배송 요구 사항을위한 콜 오프 재고 서비스를 제공합니다.

핫 태그: End Cup Bracket, Manufacturers, Suppliers, Factory, Customized, Made in China, China

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик