High pressure die casting is now considered as a popular industrial manufacturing

procedure, used to manufacture parts directly for machines or for any other

commercial or industrial production. The process allows production of accurate

products to the desired size, shape, and thickness with tight tolerances,

making it the simplest yet effective casting process, essential for creating

metal parts with specified details and quality demands.

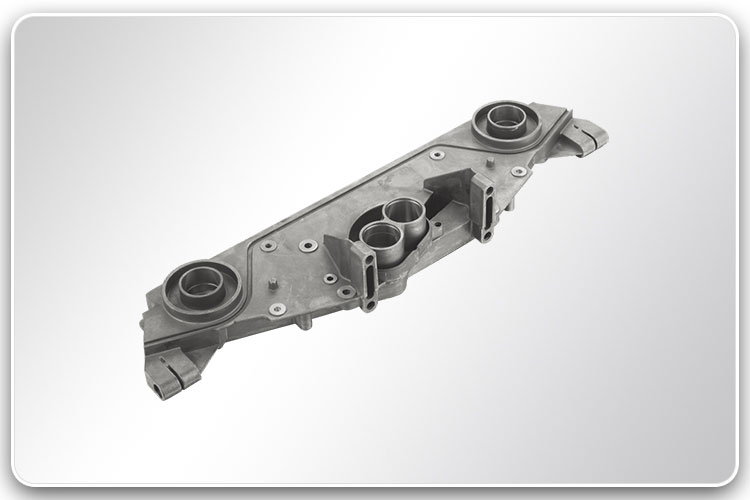

Aluminum die casting industrial parts production is an efficient,

economical process offering a broader range of shapes and components than any

other manufacturing technique. Parts have a long service life and may be

designed to complement the visual appeal of the surrounding part. aluminum die

casting industrial parts have been widely used in almost all industrial

sections including:

-항공 우주 및 방위

-Automotive

-농업 기계

-에너지

-Electronics

-구성

-교통

-산업

-Consumer Products

Auwell은 알루미늄 다이캐스팅 산업 부품 제조에 대한 고객의 요구 사항을 충족하기 위해 다양한 유형의 서비스를 제공합니다. Auwellmanufacture는 알루미늄 다이캐스팅 산업용 부품 툴링 개발, 고압 다이캐스팅, CNC 가공, 표면 처리 및 조립 분야에서 전문적이며 모든 제조 공정은 한 지붕 아래에서 수행됩니다.

Technical Specifications

-Core Element Material

H13, 1.2344 (X40CRMoV51), 1.2367 (X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

볼스터 재질 : P20,1.2312, 1.2738

-표준 구성 요소

HASCO, LKM standard or

custom made

-인기있는 제품 소재

AL226, AL230, AlSi10Mg, A360,

A380, A413 and A304 K-alloy, ADC12, ADC10 etc.

-제품 표면 마무리

Auwell aluminum die

casting industrial parts surface treatment includes but is not limited to:

brush, line polishing, high gross polishing, mirror polishing, sand blaster,

anodizing, zinc-plating, chrome-plating, nickel-plating, powder coating, silver

coating, E-coat, wet paint, silk screening and stenciling etc.

-최대 가공 폐쇄 력

4,000 톤, 부품 중량 : 5-30,000g

장점

-풍부한 경험

More than 20 years of

experience in aluminum die casting industrial parts development and production,

especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-빠른 처리

일반적으로 영업일 기준 3 일 이내에 견적을 제공합니다. 최신 제조 기술과 시설을 결합한 Auwell은 간단한 프로젝트를 위해 단 5 주 만에 초기 샘플을 제공 할 수 있습니다.

-Comprehensive Solution Provider

Auwell은 설계부터 프로토 타이핑, 툴링 / 픽스처 개발, 샘플링, 대량 생산, 물류 및 판매 후 지원에 이르기까지 알루미늄 다이캐스팅 산업용 부품에 대한 포괄적 인 서비스를 제공합니다.

-엄격한 QC 정책

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to aluminum die casting industrial parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request.

Other reports include dimensional reports, surface treatment thickness, and

salt fog test reports, etc. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

The following

catalogues of aluminum die casting industrial parts are the ones which Auwell

has produced and supplied to our distinguished worldwide clients. Please click

the relevant pictures for details. Please be advised, most of the products are

for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик