모래 주조로도 알려진 모래 주조는금속 주조 process

characterized by using sand로곰팡이 material.Gravity

casting is among the oldest known processes for fabricating metals and

metal alloys. It involves the pouring of molten metal from a 도가니 into a 곰팡이

under only the force of gravity, without the use of pressurized gases, vacuums,

or centrifugal force.

Sand casting is

commonly using for parts that have considerable big size which is not suitable

for other casting method,or the parts have very small quantity

that not worth to be made by gravity casting. Gravity casting use steel 곰팡이 with

better surface quality and higher productivity.

Auwell is very

strong in aluminum gravity & sand casting manufacturing. We are able to

develop aluminum casting parts from traditional sand casting technology

(aluminum tooling), gravity casting (Steel tooling), shell tooling casting and

low pressure casting. We have professional manufacture specially for

after-casting process including machining, fine sand-blasting, powder coating

and polishing.

The popular

material that we used for aluminum gravity & sand casting are A356, ZL101,

ZL102, ZL104, ZL106, AL107, AL110 etc., or, upon clients’ request.

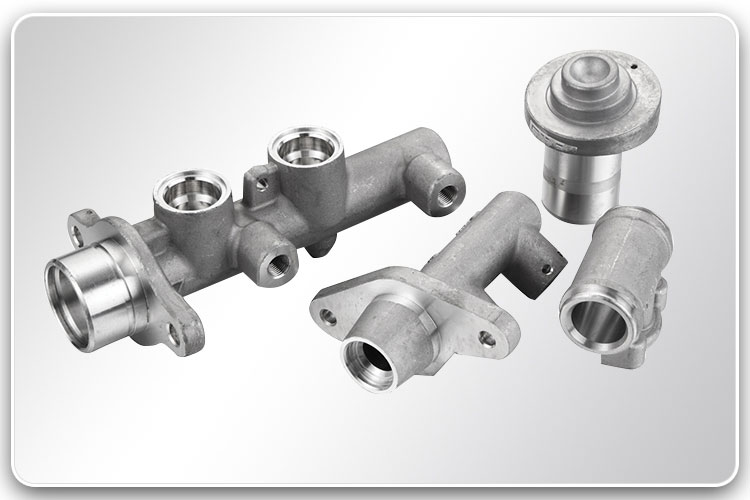

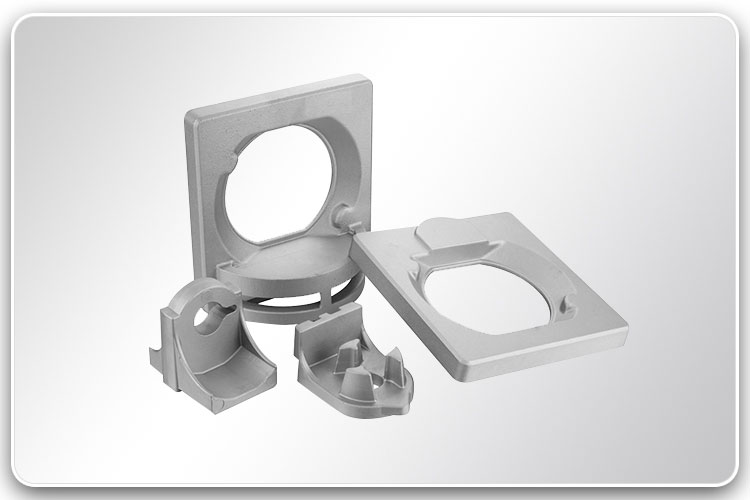

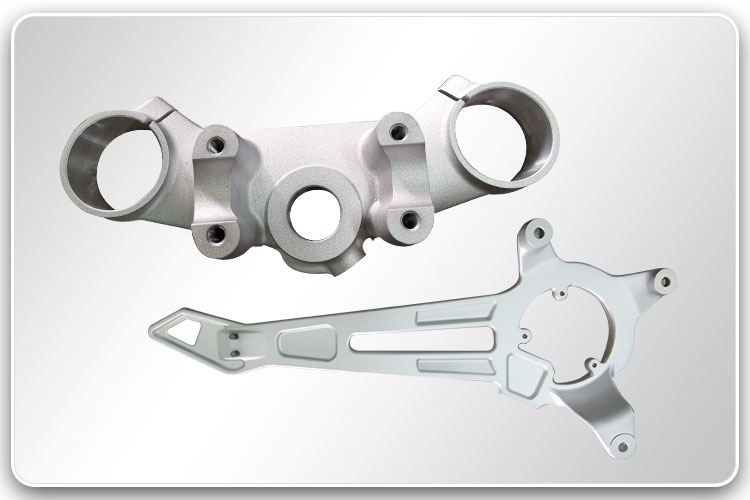

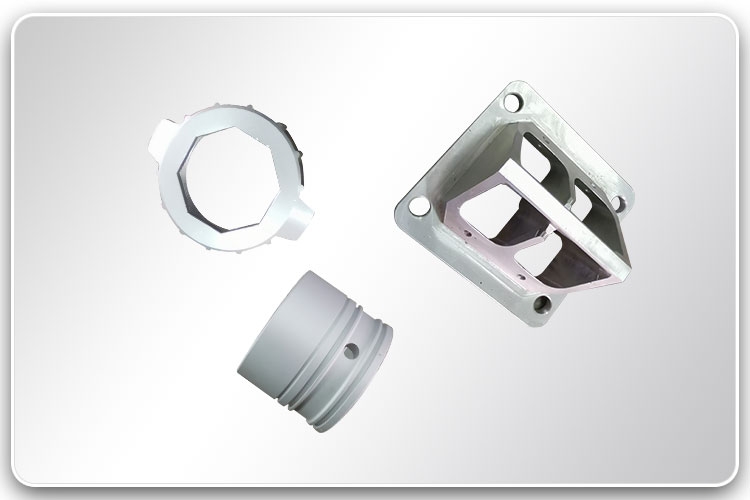

표시된 알루미늄 중력 및 모래 주조 제품 사진은 우리의 생산 능력을 보여주기위한 것입니다. 알루미늄 중력 및 주조 제품 제품 개발에 관심이있는 고객은 친절하게 문의하시기 바랍니다.

Auwell 장점

-Rich Experience

20 년 이상의 알루미늄 중력 및 모래 주조 제품 개발 및 생산 경험을 바탕으로 전 세계의 재료, 기술 및 품질 표준에 대한 확실한 이해.

-빠른 처리

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 2 weeks

for simple projects.

-포괄적 인 솔루션 제공 업체

Auwell은 설계부터 프로토 타이핑, 툴링 / 픽스처 개발, 샘플링, 대량 생산, 물류 및 판매 후 지원에 이르기까지 알루미늄 중력 및 모래 주조 프로젝트에 대한 포괄적 인 서비스를 제공합니다.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to aluminum gravity & sand casting orders. For

quality control of Aluminum gravity & sand casting parts, we provide set of

test reports including chemical components, mechanical property, X-ray test,

metallographic analysis report etc. For dimension inspection, we offer 3D

scanning report, also CMM is available for inspection. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-유연한 지불 기간

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

The following catalogues of aluminum gravity &

sand casting parts are the ones that Auwell has produced and supplied to our

distinguished worldwide clients. Please click the relevant pictures for

details. Please be advised, most of the products are for demonstration purposes

only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик